This article is part of an ongoing series on the uses for artificial intelligence (AI) in manufacturing, starting with our article introducing machine learning and AI, and their relevance to manufacturing and supply chain operations.

This article will cover how AI can be used by a manufacturer seeking to cut down on and manage the occurrence of defects in the manufacturing process. Product defects not only hurt the manufacturer in that time and money was spent to create a faulty product, but they impact the retailer who buys a product that turns out to be unsellable.

If It is Broke, Do Not Sell It

There are few experiences on this earth more disappointing than buying a product from a retail store, hurrying home at top speeds to enjoy it, tearing open the packaging to enjoy the product, only to discover—what’s this!—that the thing is broken, unusable.

A waste of money, yes, but even if you return it, it was still a waste of time, and for some of us, time is money.

Time is most certainly money for the retailers that spent time selling that faulty product and dealing with its return.

And time is especially money for the manufacturer that made and shipped that defective product to the retailer.

Manufacturers everywhere realize that defective products are the number one cause of returns, and the biggest threat to staying afloat in a competitive industry. Naturally, they will take pains to eliminate the occurrence of defective products in any way possible.

For those interested in cutting down on faulty products, whether produced on the assembly line or on the road to the retailer, an artificial intelligence solution is well worth considering.

AI as a Product Inspection Assistant

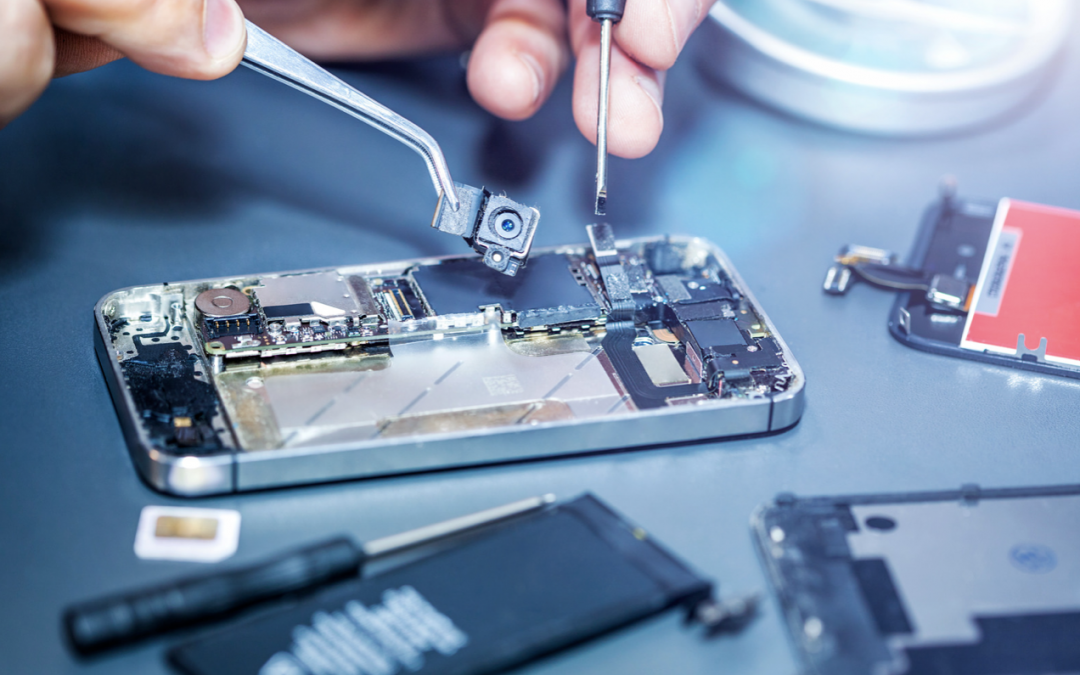

We have mentioned computer vision before, and you can bet that it plays a role in detect defection.

AI can be equipped with cameras within the factory and in trucks that can monitor the treatment of products and find out the how’s and why’s of product damage in your process.

You probably already know the most common types of defects you deal with, and AI can be trained from the outset to detect these certain types, improving over time with machine learning to get more and more accurate at detecting them.

The data this technology relies on is a combination of your own company data (pictures and videos of your own product’s defects, taken by you or a customer, can be extremely helpful) and external data about product damage in manufacturing.

The Role of Deep Learning

Machine learning teaches AI agents how to learn from data on their own, and deep learning is basically a more sophisticated version of that, employing algorithms called “neural networks” that are comprised of many nodes that each analyze the input data, in this case a picture of an object.

A neural network, and deep learning in general, exists to create more accurate analysis of data, which is important in a process like defect detection, where subtle things like lighting or positioning of an object can make it hard to tell whether a product is damaged or not.

Feature Extraction

The goal of defect detection, and computer vision in general, is feature extraction, meaning identifying the features of an image that are most important. Here, that means signs of damage.

AI-powered detection technology can work in real-time, alerting workers to a faulty product on the line so that it can be removed far before being loaded onto a truck.

This is especially useful in the early stages of a process, where a small defective part could go on to join an otherwise healthy whole, therefore ruining the entire product.

Conclusion

AI can be used to detect and prevent faulty parts and products in a manufacturing process, using computer vision and deep learning technology. This cuts down on production costs and improves customer satisfaction rates.

For more AI-powered manufacturing solutions, reach out to Findability Sciences.

More Articles in Our Machine Learning for Manufacturers Series:

- How AI Can Boost a Manufacturer’s Efficiency

- How Demand Forecasting Keeps You Ahead of the Curve

- Product Price Recommendations

- Commodity Price Prediction with AI Finds the Best Price for Raw Materials

- Transport the Goods Effectively and Safely with AI Solutions

- AI-Powered Predictive Maintenance of Machines Helps You Optimize Manufacturing Costs

- Value Creation with Artificial Intelligence

- Mass Customization Using Artificial Intelligence

- Tracking and Managing Production Floor Operations Using Artificial Intelligence

- Keeping Track of and Assessing Suppliers Using Artificial Intelligence

- Capacity Planning Prediction Using Artificial Intelligence

- Designing Products with Artificial Intelligence

- Employing Artificial Intelligence and Augmented Reality for Research and Development

Recent Comments